ComboCup

An innovative new entrant to the crowded re-usable drinkware space.

The ComboCup was conceived after looking at how people use drinkware while out and about. It was found that a seperate hot mug and cold water bottle were normally carried. The main isses with this apart from the fact that 2 seperate products are used, weas that the hot mug would leak into bags. Concepts were produced that looked at how to better integrate 2 product into one package, and avoid the leak issue.

Initial concept.

The first initial concept formed the basis for the final version. Only a few changes were needed.

Alternative concept.

An alternative "Sport" cap was designed, but after feedback it was decided that the classic bottle design should be further developed.

Final design concept.

The final concept was very close to the original, after looking at other current designs on the market that were popular, it was decided to proceed with a few aesthetic changes.

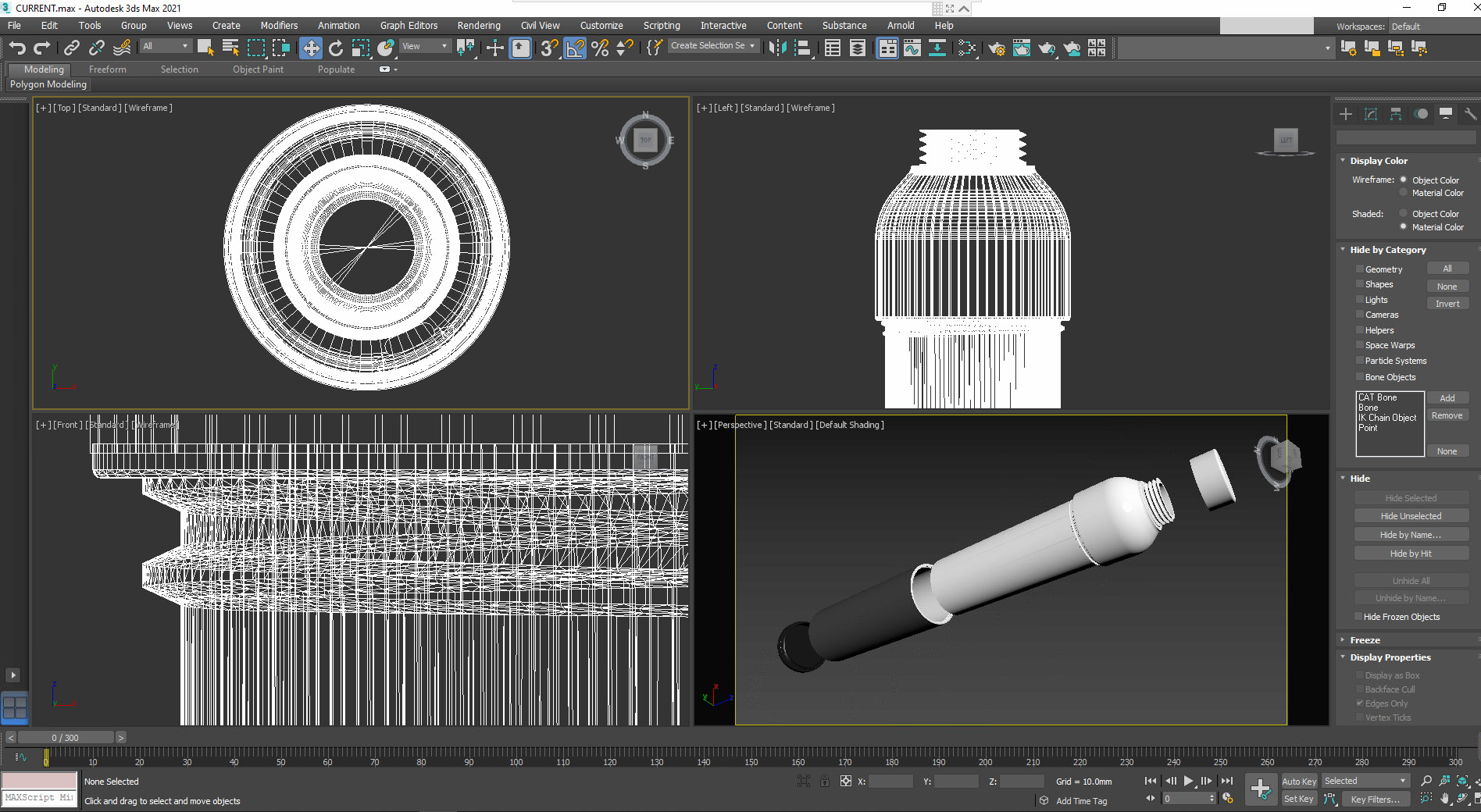

3D CAD.

3D MAX CAD drawings. These were used to generate the 3D printable files, concept renders and the promotional video.

3D printed concept model.

Once I had completed the CAD work, I 3D printed a test model to check capacity and function.

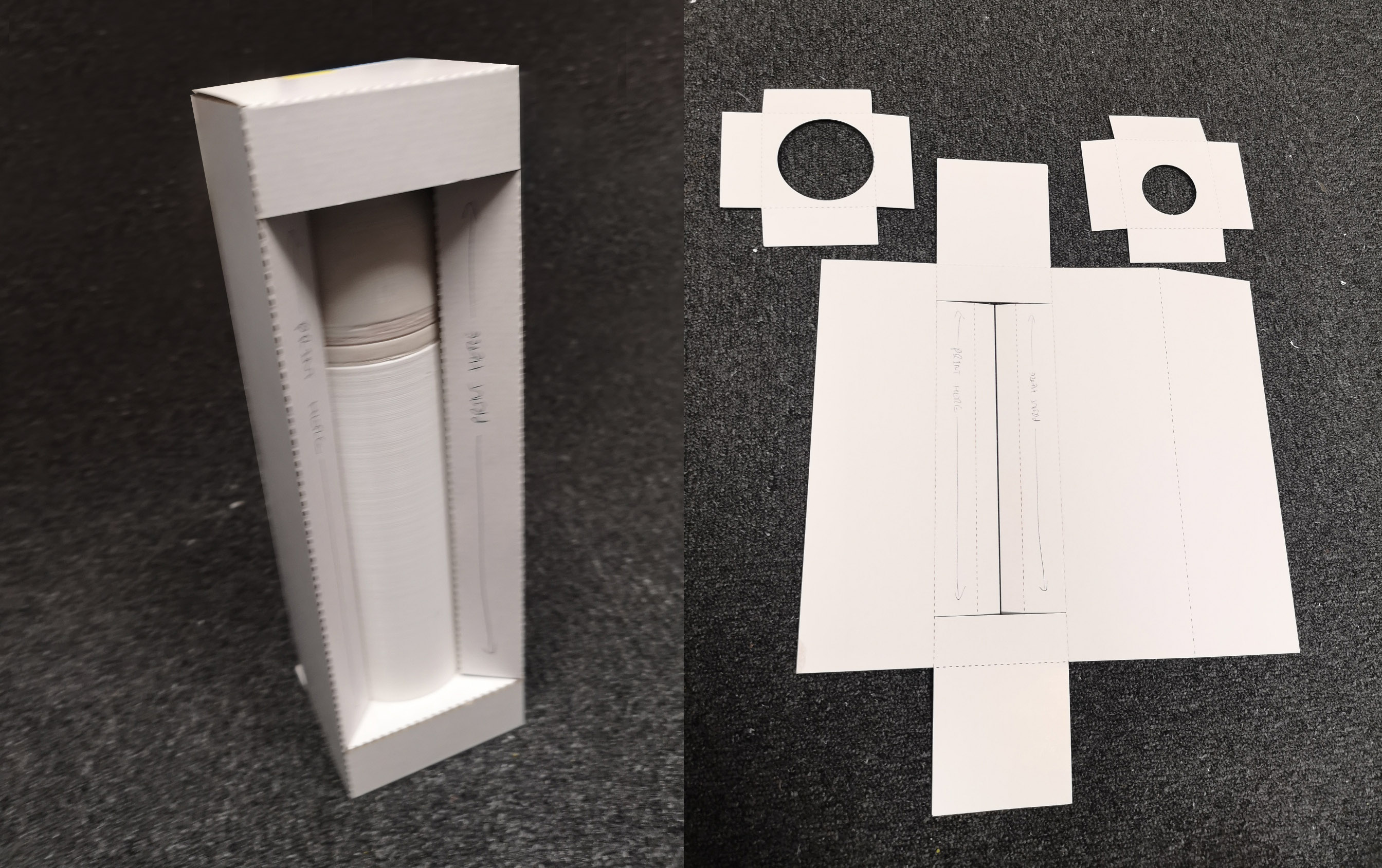

Packaging.

A unique packaging concept was needed for the ComboCup. The product materials need to be shown, without the use of plastic. I designed a cardboard window bow that has minimal wastage, and still shows the product securely.

Final product presentation video.

I created a video based on the 3D CAD files designed for the product. Rendered using Arnold for MAX and composited using Adobe After FX.

Alternative storage feature version animation.

As this product would be sold Worlwide, a USA specific version was designed. The US market favours larger capacity mugs, and extra storage was popular.

3D printed concept model.

A 3D print of the alternative larger capacity version.

Show demonstrator.

I made up a laser cut acrylic display stand with video screen playing the promotional video on a tablet. The 3D printed Combo Cup parts are held in place using stands and magnets.

More images to follow as this nears full production...

View the next product